Clogged arteries are a major problem that can lead to heart attack or stroke. Doctors can place an expandable tube called a stent into a narrowing artery to physically prop it open, but as many as half of these can eventually become clogged again.

The re-clogging of stented arteries is called restenosis, and it can be triggered by further plaque build up or by scarring around the stent. Diagnostic tests for restenosis are usually only done when a patient presents with chest pain or other symptoms.

Kenichi Takahata, professor of electrical and computer engineering at the University of British Columbia, led the development of a smart stent that could wirelessly alert doctors if blood flow begins to slow down again.

This patented prototype has been tested in the lab and in a swine model, with hopes to test a more refined version in clinical trials. The study was published in Advanced Science.

“X-rays such as CT or diagnostic angiograms, which are the standard tools for diagnosis, can be impractical or inconvenient for the patient,” said vascular surgeon and co-author York Hsiang, professor of surgery at the University of British Columbia, in a statement.

“Putting a smart stent in place of a standard one can enable physicians to monitor their patient’s health more easily and offer treatment, if needed, in a timely manner.”

What makes this stent unique is that it was engineered with clinical constraints in mind. The team wanted to be sure that their device could be implanted using conventional surgical methods, which is where many other smart stent designs have failed.

The first ever smart stent design had a planar shape before expansion, which made it impossible to guide into place using a standard stenting procedure. Others placed their chips on the outside surface of the stent, which meant that they could be easily damaged during stent crimping during insertion; they also presented a risk to fragile blood vessels that could be scratched by objects protruding from the stent surface. Still other designs relied on adhesives that could fail after implantation.

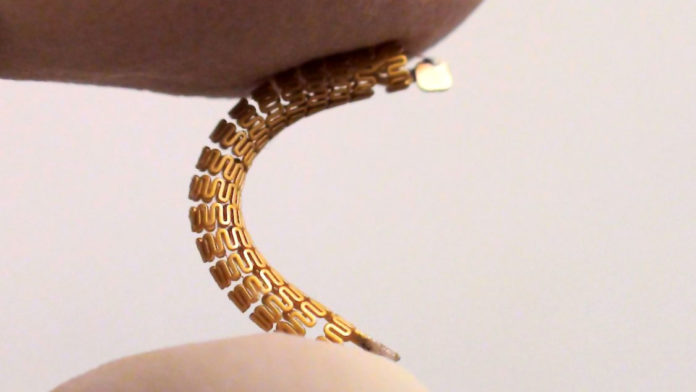

Takahata used microwelding to attach a tiny pressure sensor to the end of the stent, making it possible to implant using a standard procedure without any modifications. The entire device is constructed and coated with biocompatible materials, while being flexible, compact, and mechanically sturdy.

If this design proves successful in clinical trials, it could mean a huge improvement in response times to restenosis.