Right now our world is seeing a remarkable transformation in manufacturing. Information technology is being combined with on-site production in the form of 3D printers. This means that instead of producing items en masse in a centralized facility for distribution, inventors can design their creations, upload them to the internet, and individuals can produce them anywhere in the world, on-demand, using a 3D printer. Keith Pardee, Assistant Professor at the University Toronto, in partnership with researchers at Harvard University, MIT and the University of Ottawa, is seeking to apply the same framework to the production of biomolecules for diagnostics, healthcare, and research applications.

Biomolecules On Demand

Traditionally, synthetic biology is a field where cells are treated like factories and are “re-wired” to produce a desired biomolecule. Since production of biomolecules, or proteins, by a cell is determined by its DNA, by manipulating a cell’s DNA, bioengineers can induce it to make different proteins. These proteins can in themselves be the desired product, like insulin, or they could be enzymes that are used to construct or convert raw materials into the desired product, as is the case for some antibacterial compounds, like violacein.

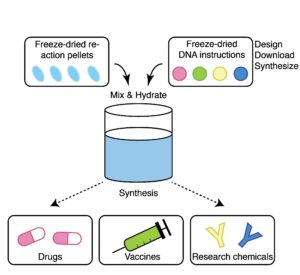

What sets Pardee apart from other synthetic biologists is that he forgoes the cells altogether. The problem with using live cells is just that—they need to be kept alive. This can be extremely resource intensive, requiring growth media, incubators, and vigilant attendants to ensure the cells are growing properly and not contaminated by opportunistic bacteria and fungi. This also means the system is not easily portable. Instead, Pardee has developed a cell-free method for doing synthetic biology. Rather than using the whole cell, only the necessary enzymes (tools) and chemicals (raw materials) are used. They can be mixed together and freeze-dried, awaiting only water and DNA instructions to activate them.

These freeze-dried mixtures of cellular components offer a couple of advantages. The first is that it eliminates the need for complicated storage. Freeze-dried pellets of enzymes and chemicals are stable at room temperature and have a much longer shelf-life than if they were kept in liquid solution. This means that costs around storage and distribution drop significantly. It also means that refrigeration is not needed, which would otherwise be important to keep many of the products stable if they were produced in a factory. Another advantage is that the instructions (DNA) can be added later, meaning that a single freeze-dried pellet could be used to make any number of proteins and biomolecules. Biomolecules can be produced on-demand just by picking the right DNA sequence.

Different biomolecules can be produced just by picking the right DNA instructions.

Downloading…

The applications for this technology are widespread, and include tools for research and healthcare. One area where this technology could be particularly useful is in the production of vaccines, especially those that need to be regularly modified and updated. For instance, the flu vaccine is made each year based on a careful prediction of the flu strains that will most likely affect us. It is then produced in factories, and shipped out to hospitals, clinics, and pharmacies. If the predictions do not match the strains of virus actually infecting people, there can be devastating consequences like in 2014-15 when the flu vaccine only had 23% efficacy. Changing a vaccine once it has already been produced can be very costly and can take up to nine months. However, if the vaccine can be produced on-demand, then updating the flu vaccine would be as simple as swapping out one DNA sequence for another.

Not only could vaccines be changed and modified on the fly, but the need for cold-chain would also be eliminated. Because the freeze-dried components are stable at ambient temperatures, unlike vaccines which need refrigeration, doctors and aid workers in remote regions could pack these freeze-dried components and safely deliver medications that would otherwise need continuous cold storage.

Because DNA is just information, this technology is useful when there are long distances between the scientists designing the molecules and the end users. Once the right DNA sequence is selected, that information can be sent across the globe and downloaded into a DNA synthesizer on-site. This completely eliminates the need to ship products long distances under refrigerated conditions and greatly reduces the risk of contamination and tampering along the distribution chain. Perhaps one day, human colonizers of Mars will use this technology to download important medications and research chemicals faster than it would take to send them across the solar system.