It may be possible to 3D print sophisticated biocompatible structures right inside the body using sound.

Current 3D printing methods use heat or light to add material to a growing structure, but that limits them to working at sub-millimetre depths just under the skin, or forces them to be paired with open surgery.

Muthukumaran Packirisamy, professor of mechanical engineering at Concordia University, is going a different route by investigating using focused ultrasound waves instead because they can penetrate deeper into tissue. Packirisamy and his team used their technique with injectable liquid resins of a curing agent and poly(dimethylsiloxane), a polymer that is commonly used in tissue engineering. Their study was published in Nature Communications.

Using focused ultrasound as an energy source, a phenomenon called cavitation happens near the focal point, producing tiny bubbles with extremely high temperature (over 15,000 degrees Kelvin) and high pressure (over 1,000 times greater than atmospheric pressure).

These bubbles act like tiny reactors: chemically active hotspots that can deposit newly solidified material onto a growing structure. Curing the resin from a liquid to a solid happens in trillionths of a second.

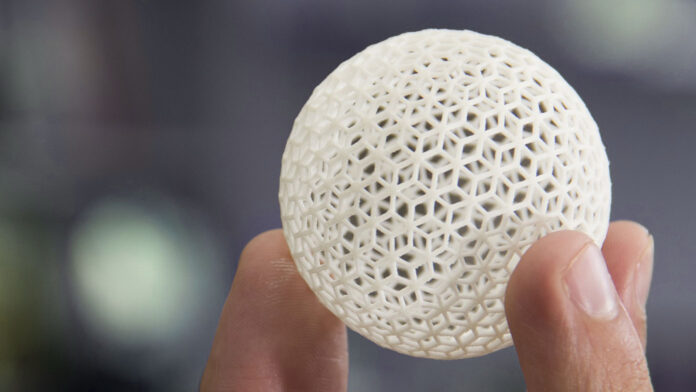

The bubbles heat up and cool down quickly, leaving the surrounding resin unchanged and allowing complex geometries to be printed. Features as thin as 100 microns could be printed (about the thickness of a standard sheet of printing paper). The technique was also tested through 15 millimetres of porcine skin, fat and muscle up to a final printing depth of 33 millimetres.

This versatile approach to 3D printing solid structures in the body could be used to pattern biosensors or medical devices using minimally invasive methods, possibly avoiding surgery altogether. This would help with patient recovery times if procedures become possible through a needle instead of an incision.

“Ultrasonic frequencies are already being used in destructive procedures like laser ablation of tissues and tumours. We wanted to use them to create something,” said Packirisamy in a press release.

“We proved that we can print multiple materials, including polymers and ceramics. We are going to try polymer-metal composites next, and eventually we want to get to printing metal using this method.”