Tablets you can roll up like a sheet up newspaper; a skin patch providing real-time medical diagnostics; clothing that can change temperature depending on the weather. No, this isn’t a prop list for the next sci-fi movie. These are products that could be in our future. But first we need to overcome some of the technological hurdles so these seemingly far-fetched concepts can become a reality.

Researchers from around the world are already tackling some of the major challenges associated with flexible circuitry, displays, and even going so far as to develop wearable skin patches (e-skin). One major piece of the puzzle that remains is developing a flexible battery that can withstand repeated stretching, bending, and folding. It also needs to be inexpensive, making this technology affordable to everyone and to be environmentally benign, getting around a major burden of current batteries.

Overcoming these challenges might not be far off. The Seferos Research Group at the University of Toronto has developed a plastic lithium-ion battery cathode material derived from Vitamin B2 that has the potential to meet the needs for a flexible battery head on.

Batteries have two electrodes: an anode, the negative electrode; and a cathode, the positive electrode. The potential energy difference of the electrodes gives the voltage of the cell. When the battery anode and cathode are connected in a circuit, charge flows, creating a current that carries electrons from the anode to the cathode. This current can be used to power a device within the circuit.

Cathode materials for lithium-ion batteries are typically made from heavy metals such as cobalt. The Seferos Research Group has focussed on replacing these materials for three reasons: 1) they are expensive, 2) they impose an environmental cost to make, only partly reduced by recycling, and 3) they have limited mechanical flexibility.

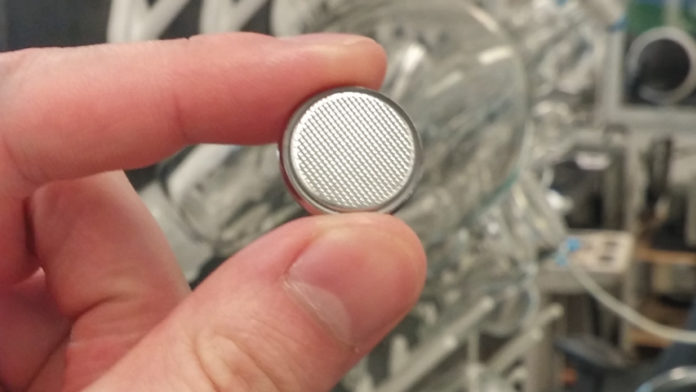

By deriving materials from biological sources, both the cost to consumers as well as the environmental footprint of manufacturing and disposal can be reduced. Being a plastic, this material offers advantages of flexibility, ease of processing, and even transparency. While still at the research stage, the Seferos Research Group has demonstrated this concept in a typical coin-sized battery. The prototype has a capacity of 125 mAh/g and voltage of 2.5 V, which is competitive with what is currently on the market.

The Seferos Research Group is currently working on improving the performance and durability of their vitamin-powered battery by tweaking its molecular structure. The next step – construct a prototype capable of powering flexible and wearable electronics. That sci-fi prop list may be just around the corner.