Penguins are adorably clumsy and awkward on land. But in the ocean they are completely in their element, gliding through the ocean as powerful predators that are so graceful that they look like they are flying.

The water is where they spend 75 percent of their lives. Yet despite this highly aquatic life in the frigid climate of Antactica, penguins manage to keep their pelts remarkably ice-free.

By mimicking the microscopic structures of their feathers, researchers at McGill University have crafted a fine steel mesh that can readily shed ice without any chemical treatment. It could one day prove to be a launch point for keeping important structures clear of ice.

Their study was published in ACS Applied Materials & Interfaces.

Today’s de-icing strategies come in two main forms, each with drawbacks. Chemical de-icing can have destructive impacts on the environment and our infrastructure after the chemical agents done their job. And physical de-icing requires machinery to actively be at work wherever ice may be building up, which can be impractical over large areas or for structures that are in motion like wind turbines. When these strategies fail, major events like widespread power outages can happen.

The key to the penguin feather-inspired mesh is that it tackles de-icing using a dual-pronged strategy.

“We initially explored the qualities of the lotus leaf, which is very good at shedding water but proved less effective at shedding ice,” said principal investigator Anne Kietzig, associate professor of Chemical Engineering at McGill, in a press release.

“It was only when we started investigating the qualities of penguin feathers that we discovered a material found in nature that was able to shed both water and ice.”

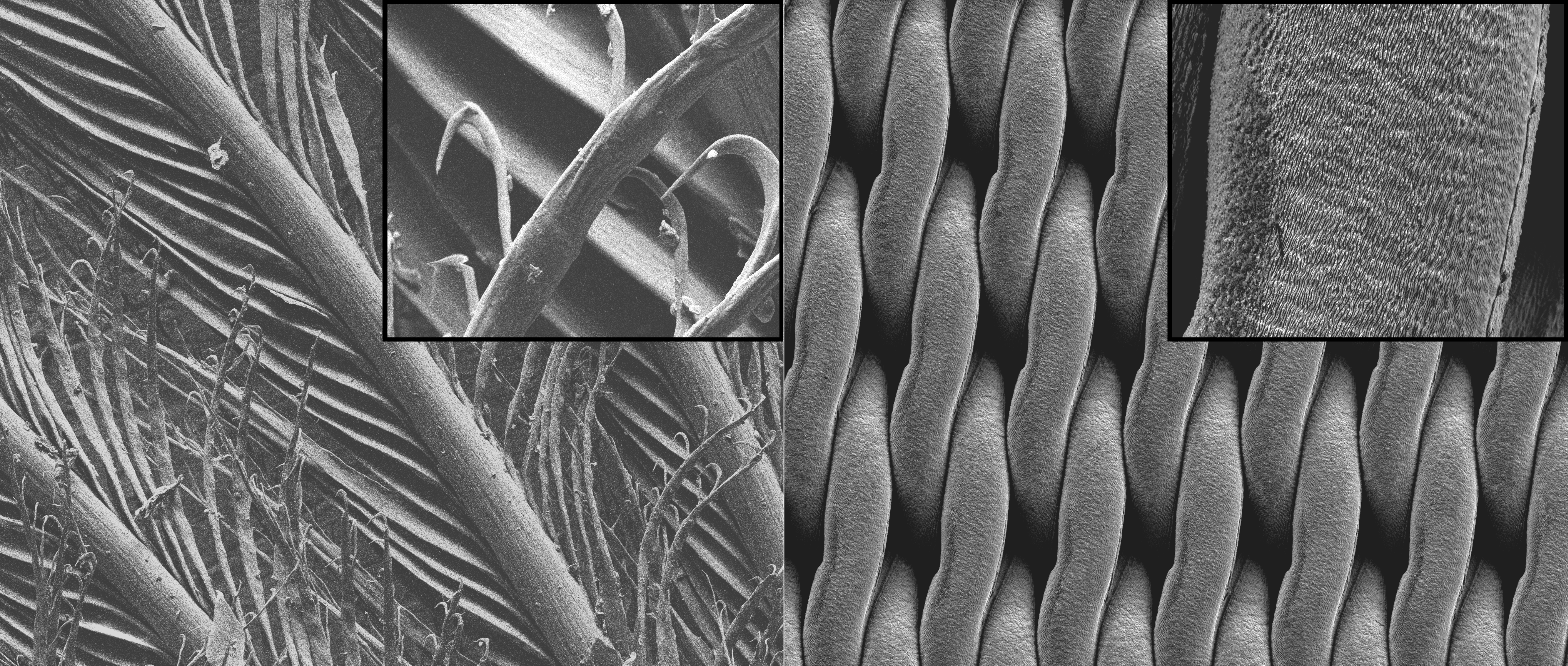

Keitzig and her team used laser micromachining to mimic the feathers’ microstructures, producing a woven wire cloth made out of stainless steel. Like the feathers, the cloth features an array of tiny pores where water can gather and turn into tiny ice cubes.

“It may seem counter intuitive, but the key to ice shedding is all the pores of the mesh which draw water in under freezing conditions,” added co-author Michael Wood.

“The water in these pores is the last to freeze, creating cracks when it expands, much like you see in the ice cube trays in your freezer. We need such little force to remove ice from our meshes because the crack in each of these pores easily snakes along the surface of those woven wires.”

In addition to the physical features of the cloth, the laser micromachining technique leaves a surface chemistry that turns into a water-repelling surface in 3-4 weeks with simple exposure to the air. Organic compounds that are naturally present in the air stick to the surface to produce this spontaneous coating. This water-shedding property is similar to how penguins preen using oil from a gland near the base of their tails.

Compared to a standard sheet of polished stainless steel, surfaces covered with the biomimetic steel mesh were 95 percent more effective at resisting ice build up when tested in a wind tunnel.

With no need for a chemical coating, these structures could provide a maintenance-free approach keeping wind turbines, electric towers and power lines, or airplane wings free of ice. The current mesh is thin like a metal foil, but the technique could be applied in a more stable and permanent way.

If this sustainable strategy can be integrated into our infrastructure, it will be possible to save time and energy, while reducing environmental harm — a solution that is far less clumsy and awkward than the options we have today.